Tailored Testing for Evolving EV

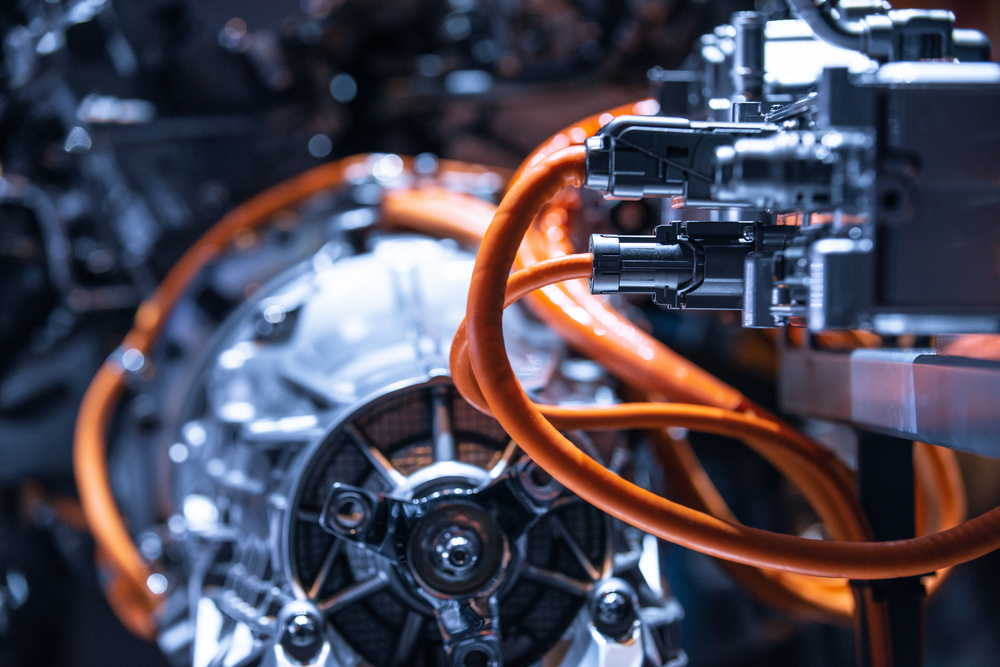

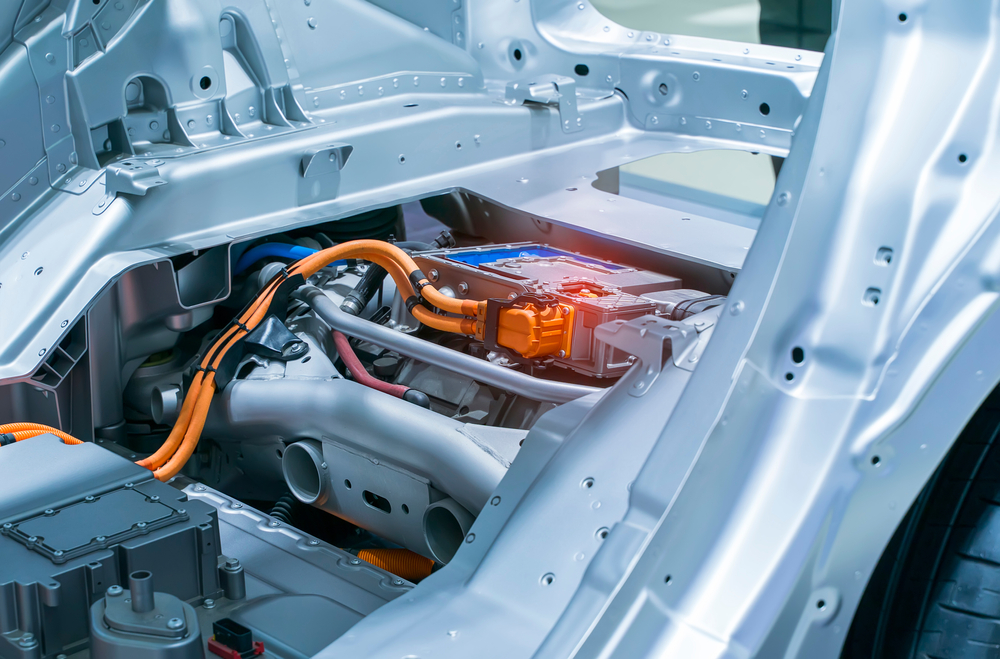

Think your current testing strategies can keep pace with today's electric vehicles? Think again. As EV systems become more complex, outdated testing techniques lead to delays, errors, and failures in the field. Testing strategies must advance alongside EV innovation. That means moving beyond one-size-fits-all fixed testers to tailored testing approaches for mission-critical systems, including powertrain, battery management, sensor and management, and in-car network and communication systems.

Evolving EV testing requires an experienced collaborator who can provide strategic guidance specific to your components and development stage. A knowledgeable partner understands the nuances of core system testing and the necessary methodologies for comprehensive validation. Collaborating with an expert early in the design process keeps your EV testing on pace with advancing technology.